خلاصہ

I am a safety-conscious and strategically agile Head of Department/ Team Lead with extensive experience of Chemical Engineering, Quality Management, HSE, and Planning within production and manufacturing field. I am instrumental in planning production schedules over multiple shifts and streamlining production processes, while operating in a time constrained environment. Drive success in achieving accuracy and problem solving utilizing lean manufacturing procedures to reduce costs. I am a resourceful leader train and motivate teams to peak performance, build and maintain strong relationships at all professional levels, develop and create various quality products to achieve production goals.

My key skills include Quality Assurance & Control, Project Complete Life Cycle, Continuous Improvement, Environment Health & Safety, Material Procurement & Availability, Staff Productivity Improvement, Production Planning & Control, Reporting & Technical Documentation, Technical Troubleshooting, Chemical Cleaning Services, HR Support Functions and Cross-Functional Skills

Currently I am engaged with Khawaja Mineral Industries (Pvt) Ltd, as a Team Lead Quality Assurance (QA) and Production Planning & Control (PPC), where I develop standards for quality of production and define what is acceptable and what is not acceptable in liaison with CEO. Attached is my resume which showcases my progressive experience and successful track record for leading successful initiatives. My professional background and great industrial exposure coupled with an excellent track record makes me an ideal candidate for executive roles. As such, I would welcome a discussion regarding opportunities with your organization that fit my background.

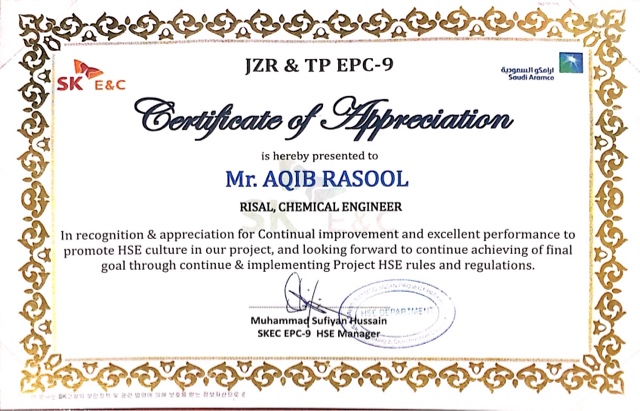

پراجیکٹس

تجربہ

Team Lead Quality Assurance (QA) and Production Planning & Control (PPC)

Performed duties under direct reporting to CEO, ensured product compliance with defined quality standards, completed Production Planning & Control function of KMIPL, and handled tasks delegated by CEO related with (QA) and (PPC) operations.

Developing Acceptable Quality Criteria

• Develop standards for quality of production and define what is acceptable and what is not acceptable in liaison with CEO.

• Liaise with concerned staff in assessing customer’s quality requirements and ensure to implement procedures for testing.

• Exercised hands-on approach to ensure that the quality testing standards meets the customer compliance requirements.

QA of Incoming Material from Sites

• Led core inspection or testing of incoming raw material through QA inspector at site as per defined quality parameters

• Delivered sterling support with CEO for any deviations in quality parameters of incoming material for necessary action.

QA during Production

• Devised quality control during production, kept CEO abreast with all issues faced in production process with deviates from quality standards. Reviewed the quality approval/rejection reports from QA staff and share with CEO.

• Managed tolerance variations in quality or any other specification coordinate with concerned staff, on priority basis and act accordingly to take suitable decisions, ensured the final product received for final dispatch is free of quality defects.

• Ensured optimum quality as per defined standards within tolerance limits in each production section by QA inspections.

Re-Work Minimization

• Controlled and monitored operational activities of QA staff on regular basis and updated all quality of raw material used and final product, also steered efforts towards minimizing re-work ratio received during final quality inspections.

Chemical Engineer

Supervised all operational projects as well as in technical processes to all the Commissioning/Pre-Commissioning activities

• Directed all functions related with Chemical Cleaning, Lube Oil Flushing, Steam and Air Blowing, and Hydro Milling.

• Led Decontamination (Hydrocarbon, Mercury & NORM) and Neutralization and Tanks cleaning & passivation.